FABO ACADEMY X

CLASS 3

Introduction 2 Additive Manufacturing

View Boibee on GitHub

Visit Course Page

HAPPY NATIONAL DAY! XD

Pzzzzzzzzzzzzzzz….Here comes 3D Printing!

3D PRINGTING WORKFLOW

- 3D Design File (Fhinoceros, Fusion 360 …)

- Slicing (Slic3r, Cura, Makerbot Print)

- Printing(Gcode)

3D PRINGTING NOTES

-

Wall Thickness/Shell Thickness(nozzle size)

(0.4 0.8 1.2 depend on the nozzle size Thickness = n * nozzle_size) -

Minimal Gap of separation between moving parts

(the moving part gap should bigger than the nozzle_size) -

Overhang(45 degree rule)

-

Layer Height

(n * nozzle_size) -

Bridging: Print in the air

-

The testing modle

-

When using 0.4 (equal to nozzle_size gap ) something wrong may occur to the Wall

-

Printing gap

0.3 -> fast0.2 -> more details0.1 -> really really detailsNEVER 0.4!!!

CHEESE PHONE HOLDER 1.0

-

Modeling a lovely cheese, which seems to be bited by a mouse, as a phone holder.

-

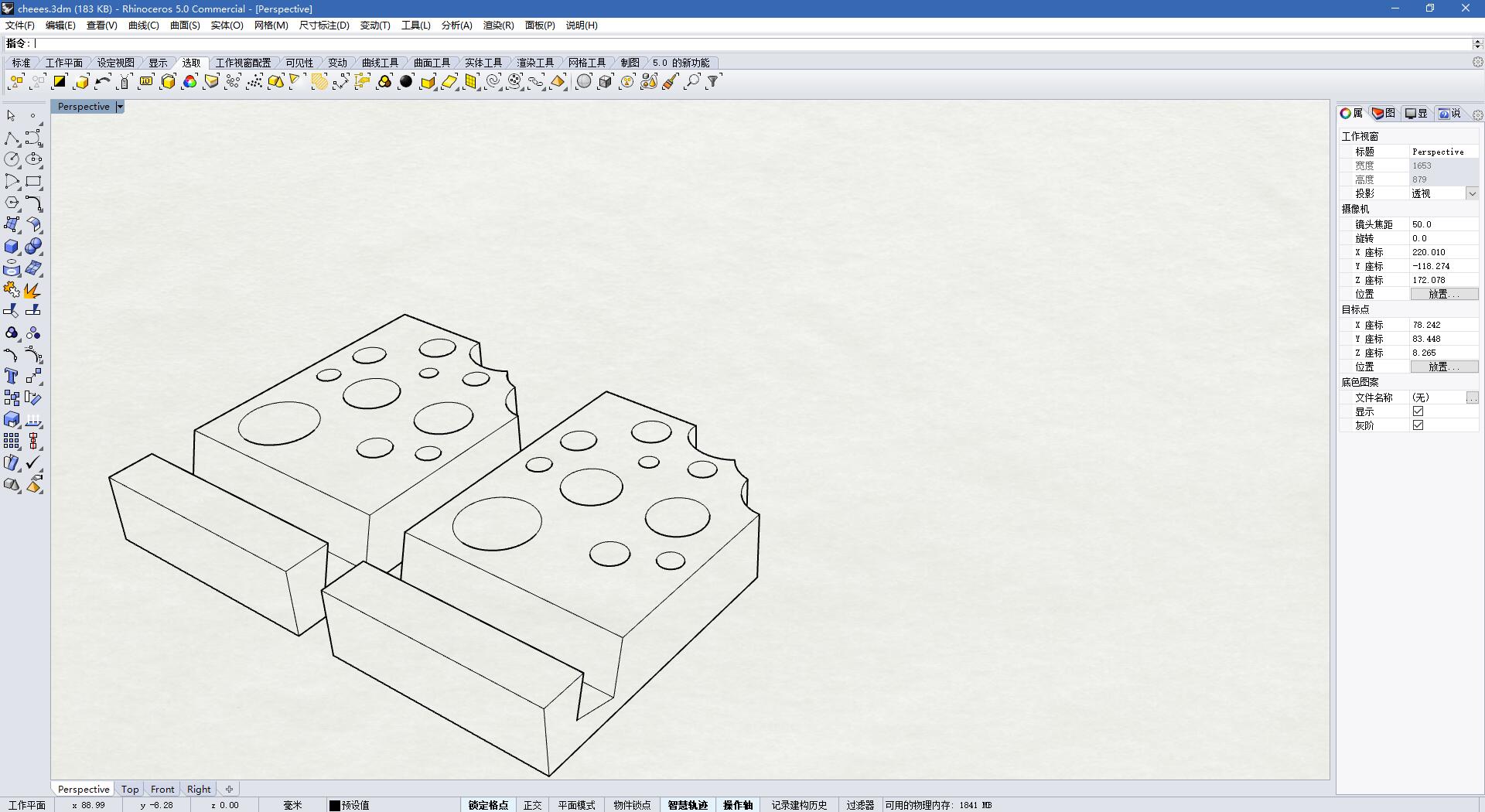

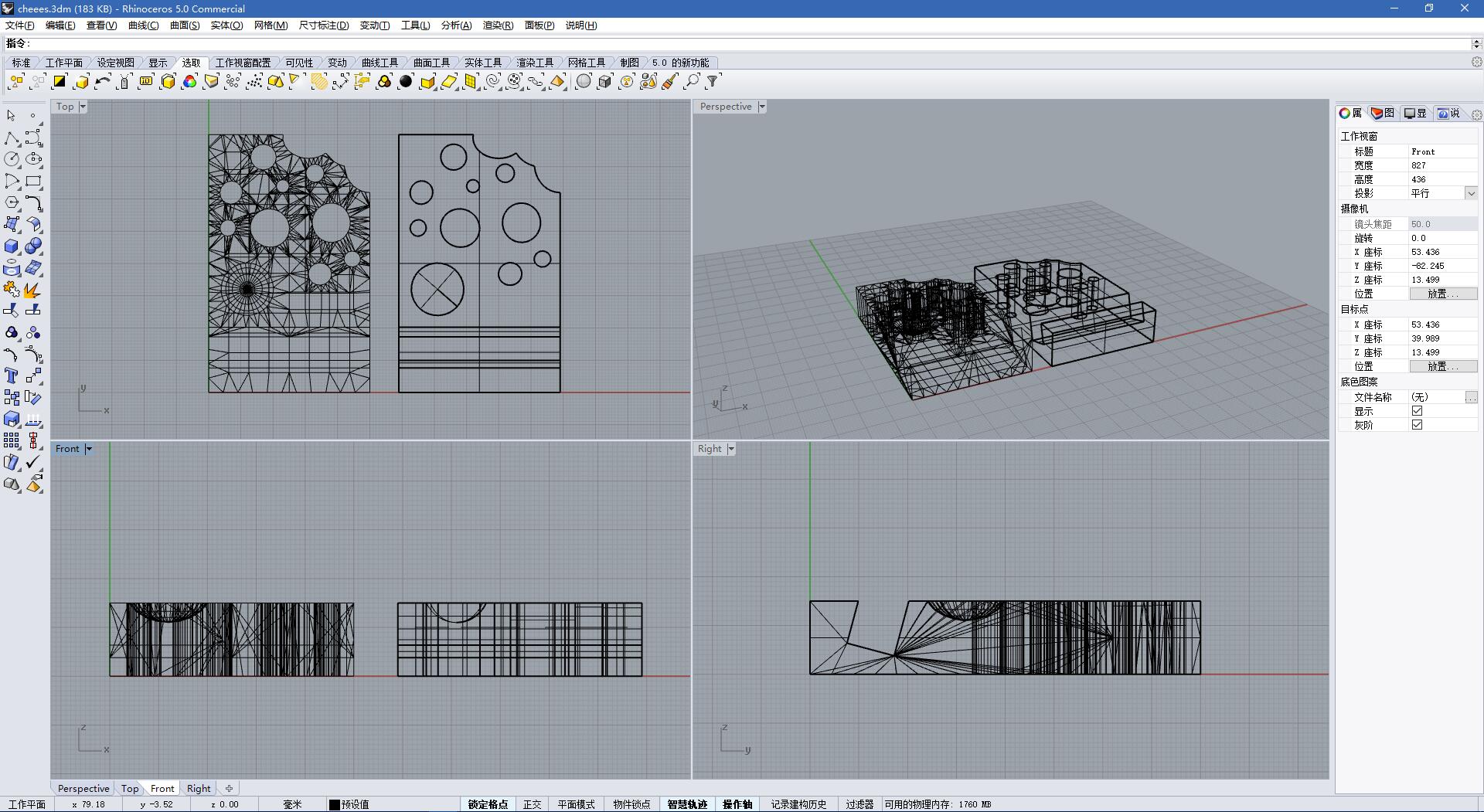

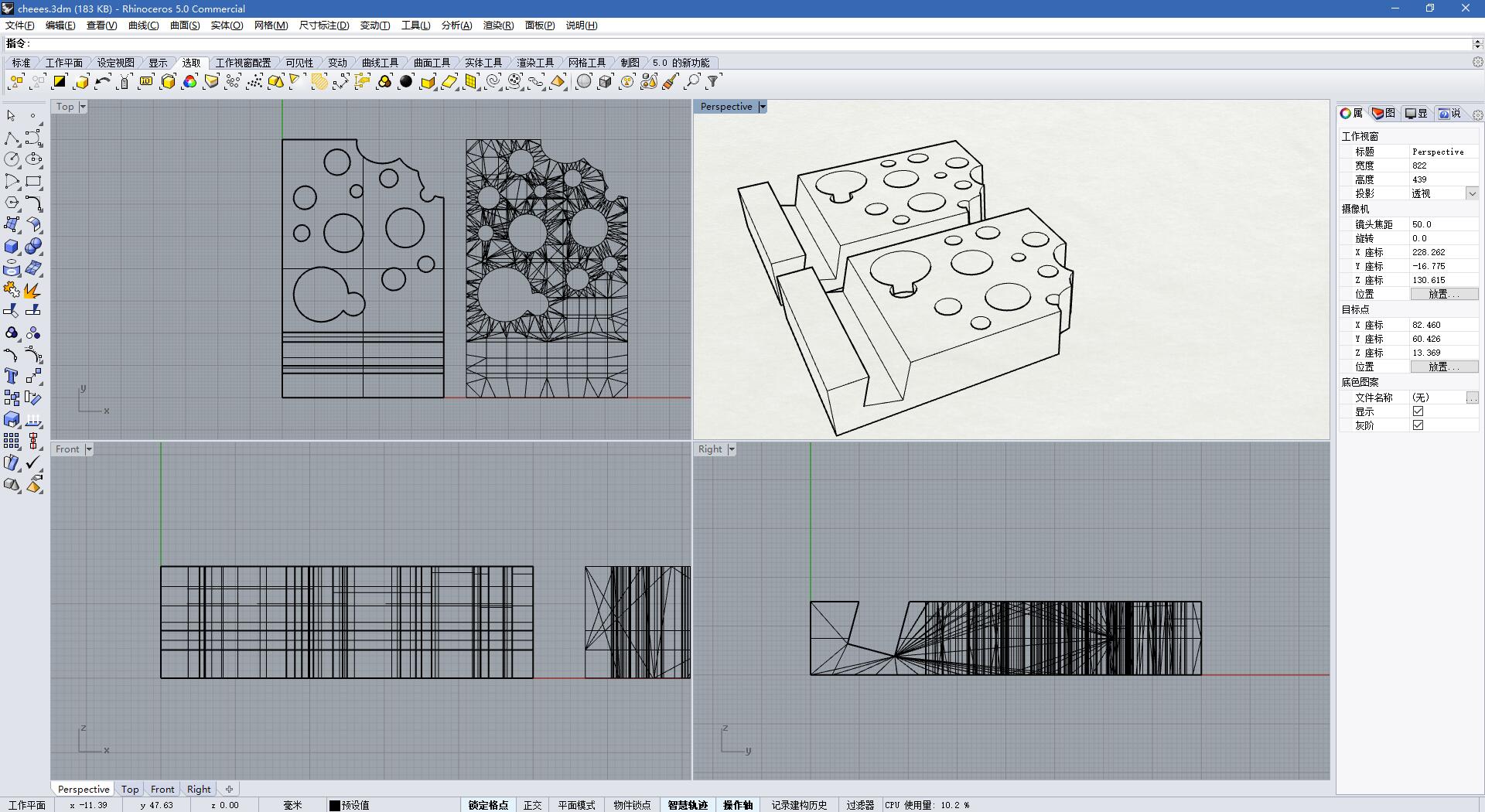

Modeling with Rhino5

-

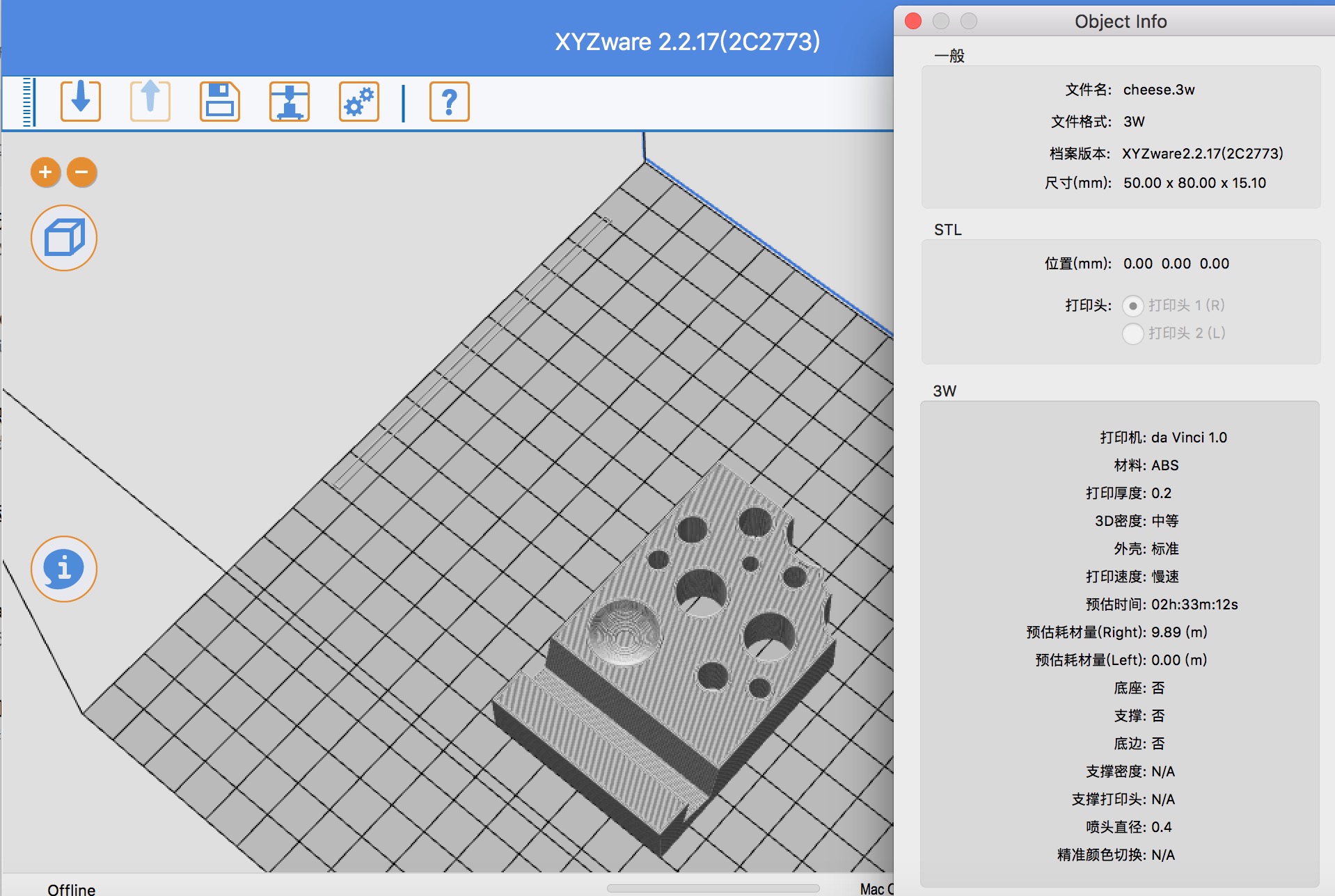

Dowloading XYZware based on da Vinci 1.0

-

Creating a Mesh file

-

Printing setting data to Cheese 1.0

-

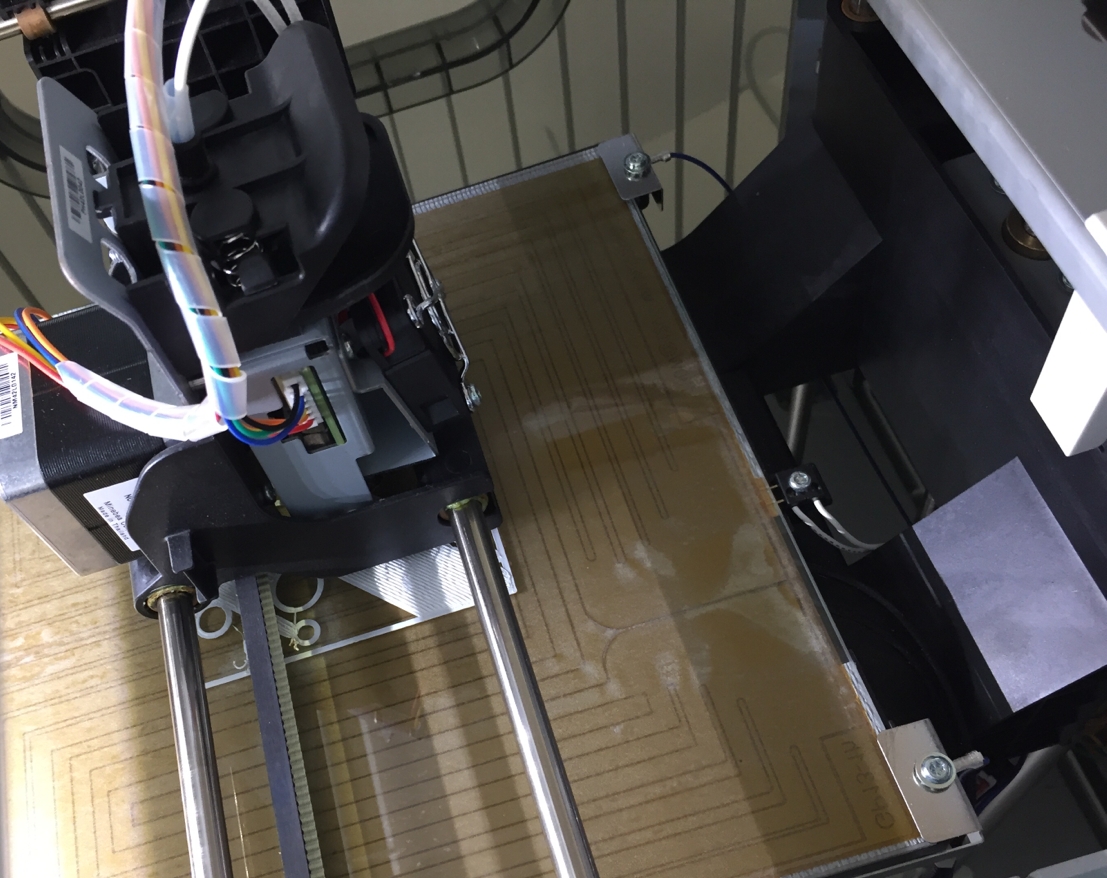

Printing Cheese 1.0

-

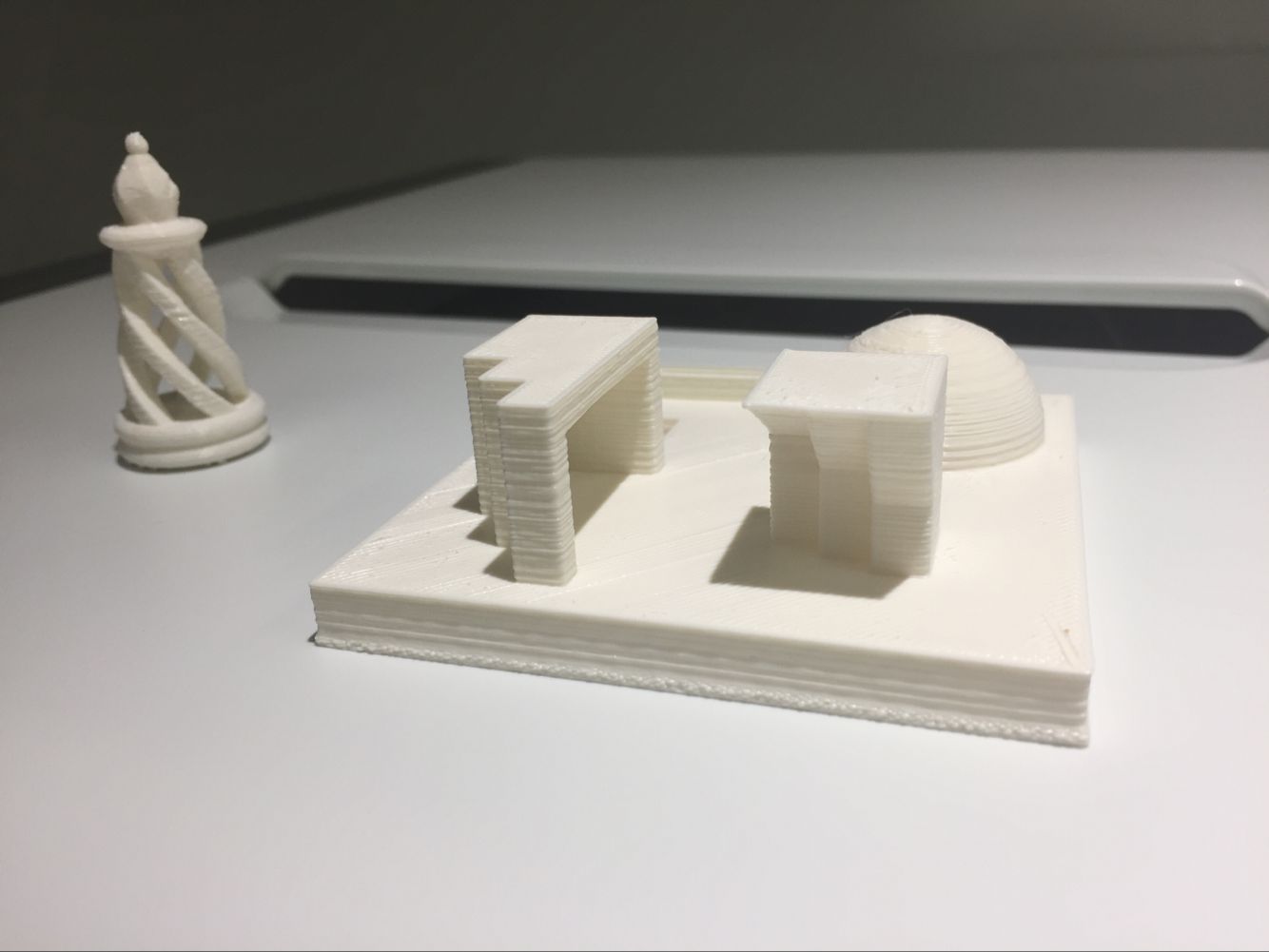

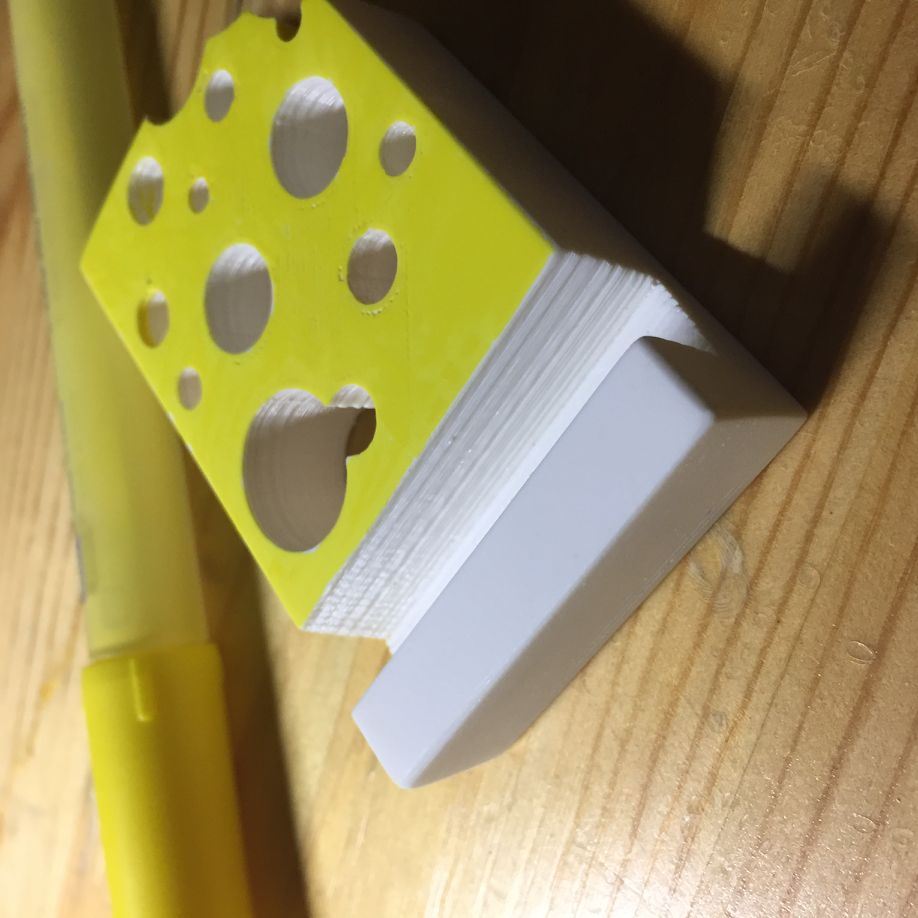

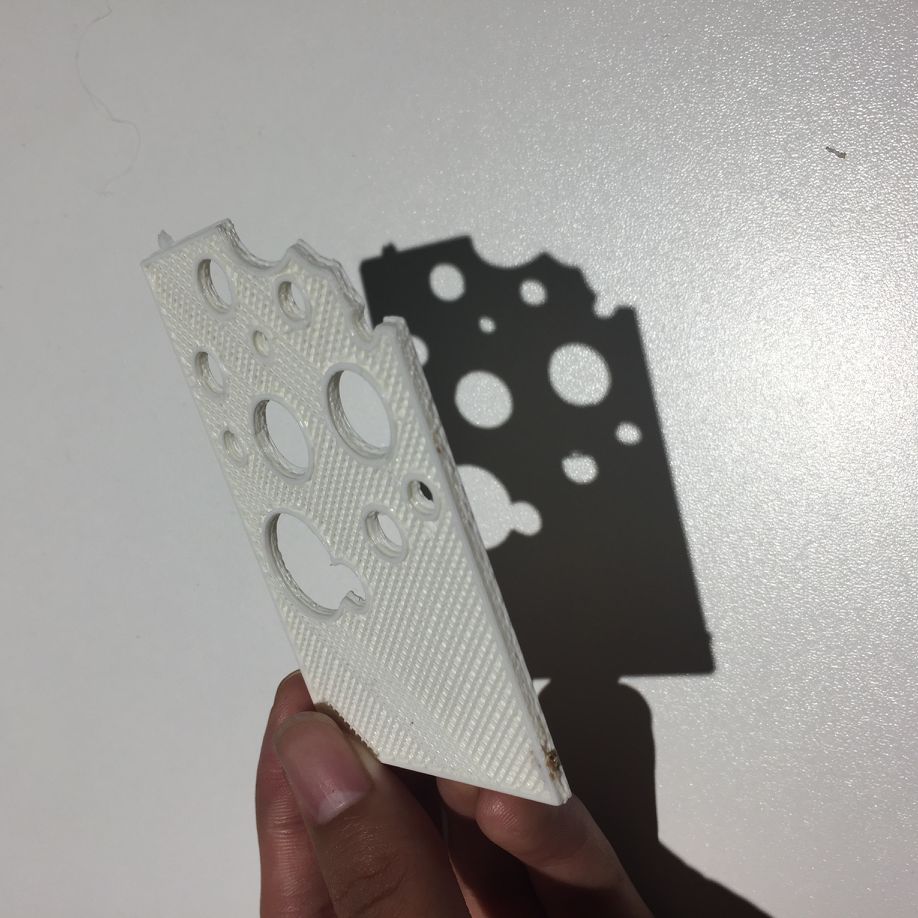

Prototype of Cheese 1.0

CHEESE PHONE HOLDER 2.0

-

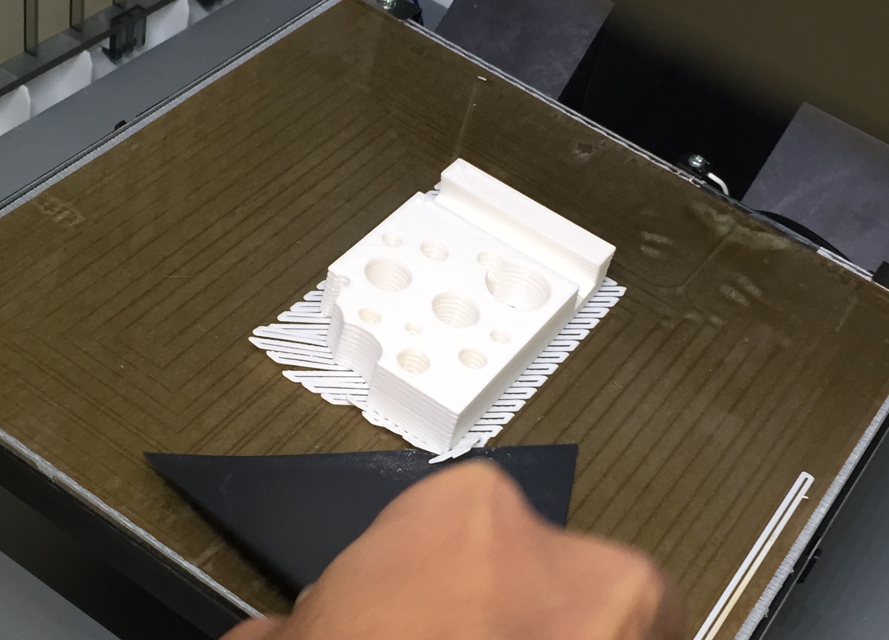

Cheese 2.0, with more cheese details and alse applying smoothing method!!!

-

Mesh file of Cheese 2.0

-

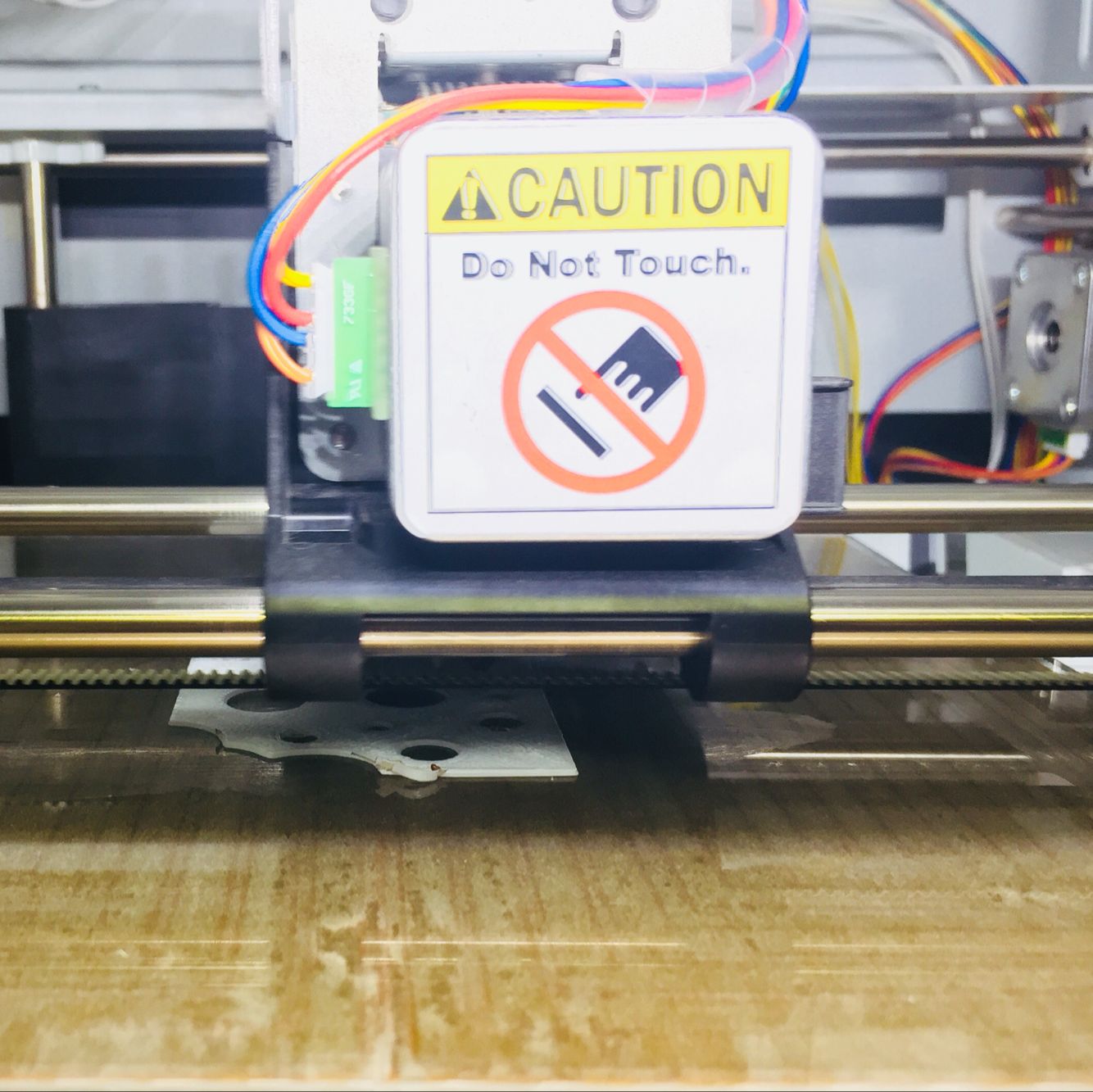

Cheese 2.0 on Printing :D

-

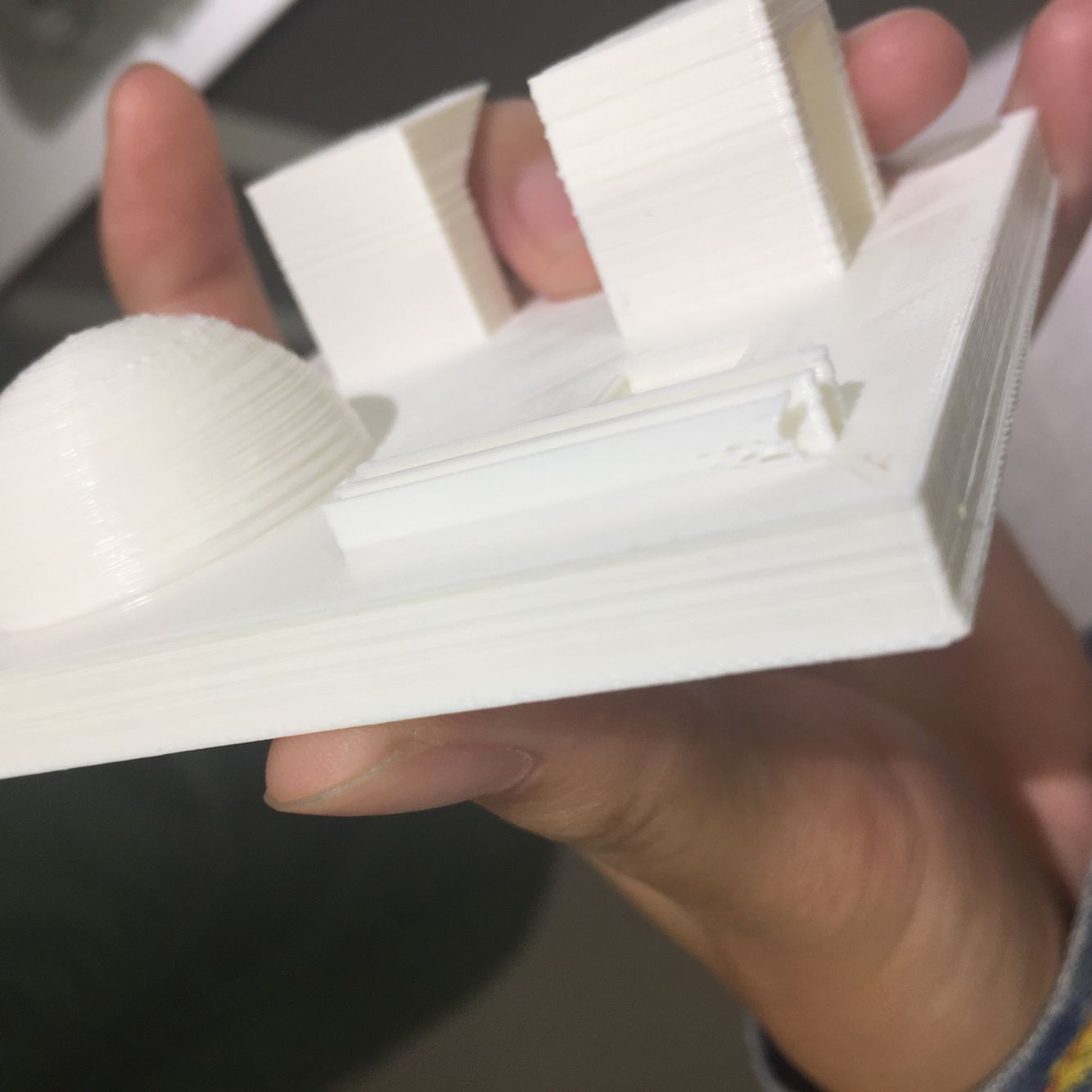

Prototype of Cheese 2.0

RELATED LINKS

- THINGIBERSE

- RepRap online communittee

- Dowload Cheese1.stl

- Dowload Cheese2.stl