FABO ACADEMY X

CLASS 2

Introduction 2 Laser Cutter

View Boibee on GitHub

HAPPY NATIONAL DAY! XD

Bzzzzzzzzzzzzzzz….Here comes CO2 Laser Cutter!

LASER CUTTING OPERATING THE MACHINE

- Turn on the laser cutter, the airflow and the exhaust filter.

- Insert a sheet of material.

- Focus the laser head.

- Send the file from PC to the laser cutter.

- Use laser cutter control panel to start cutting.

(When the machine is ready to cut, it will "bibi")LASERS CUTTER SAFETY

- Ensure good ventilation.

- Airflow and filter must be ON.

- Only cut safe material

(using flame test) - NEVER EVER leave the laser unattended while cutting.

(no farther than an arm length between u and the machine)

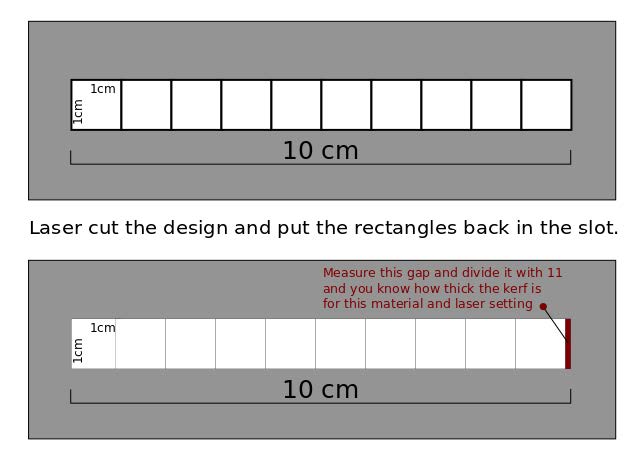

KERF CALCULATION

- The laser burns away a portion of material when it cuts through.

- This is known as the laser kerf and ranges from 0.08mm – 1mm depending on the material type, its thickness and laser settings (power, speed, PPI).

- To calculate the kerf:

FASTER SHAPE ENGRAVING

- When engraving, laser swings left to right and moves bottom to top.

- To avoid smoke stain use masking tape.

(laser settings must be modified)

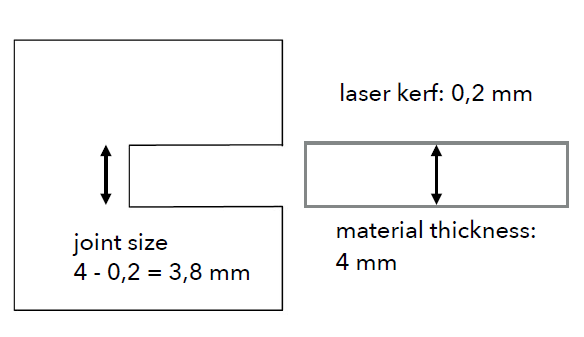

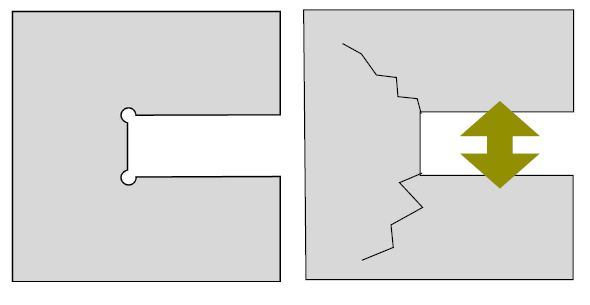

PRESS FIT JOINTS

- KERF should be counted.

- Or you can make a TRICK two little holes will be helpful.

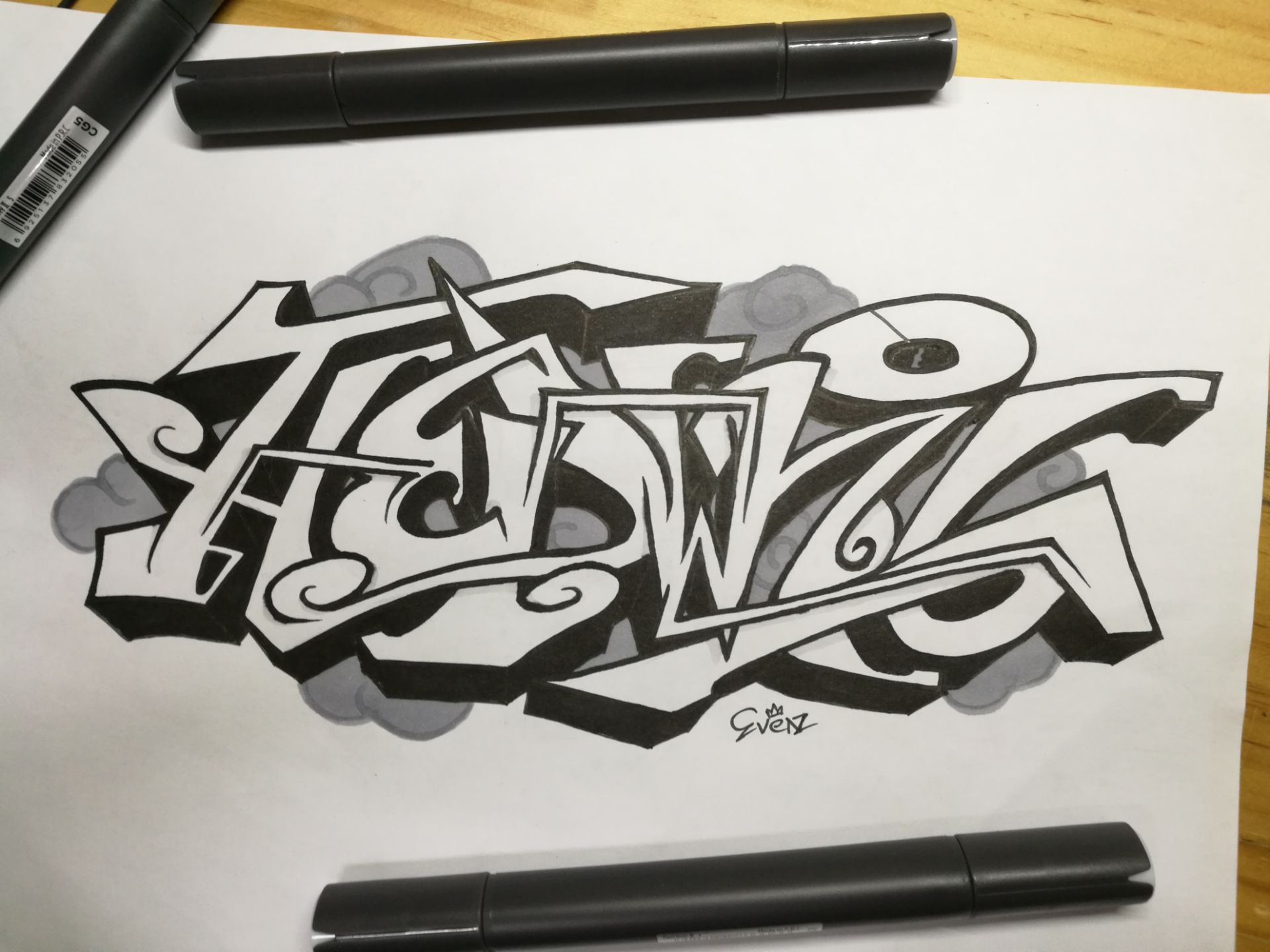

DESIGN ADN CUT A NAME TAG WITH A STAND AND FRESS FIT JOINTS

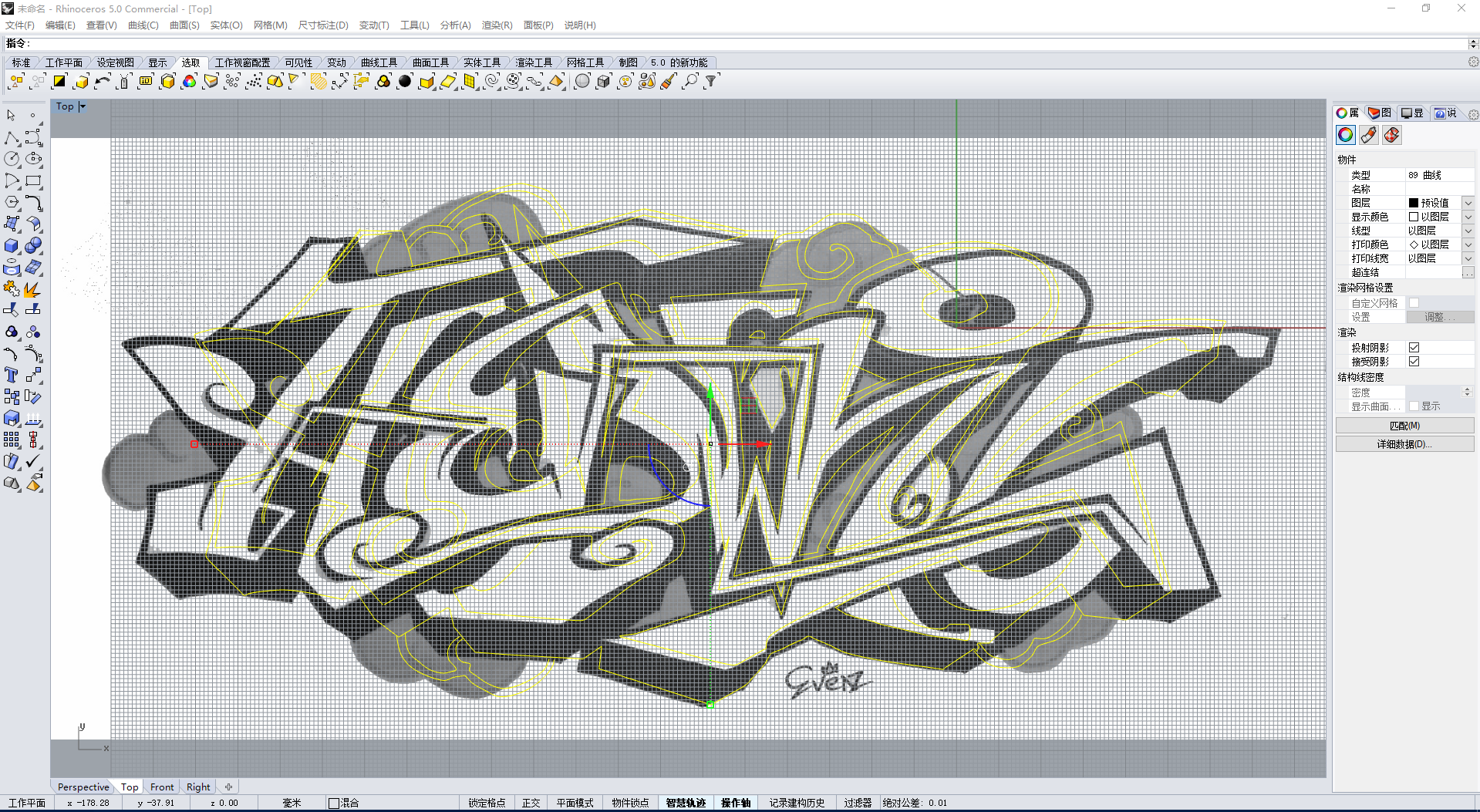

- Original graffiti design by my friend Yang Zhang

- Sketch in Rhinoceros

- Raw Prototype from Laser Cutter

- Click the link to view Hedwig 2.0

- Hedwig 1.0

- Hedwig 2.0

.jpg)

RELATED LINKS

- Dowload Hedwig.dxf

- Dowload Hedwig.3dm